Products

Engine & Transmission Treatments

Fuel System Treatments

Industrial Lubricants

BLI's Liquid Boron Engine Treatment products are designed to provide "Long Life Friction and Wear Reduction" for today's high tech engines and yesterday's heavy duty power producers. BLI's engine and gearbox products are not just additives but treatments designed to bond with and protect engine components with a diamond hard boundary lubrication layer that significantly reduces friction between the moving engine components. BLI's Liquid Boron regenerates after the initial treatment and continues to provide long life oil change after oil change.

BLI's unique chemistry is compatible with all types of engine oils - synthetic, semi-synthetic and mineral. Each Liquid Boron product works with and enhances the capability of today's modern engine oils.

Whether you are in construction, commercial trucking, agriculture, commercial fleet, busing, rail transport, recreation or marine transport, you have an engine that BLI's Liquid Boron can protect while improving fuel economy and reducing operating costs.

See our line of engine and transmission treatment products below:

Engine & Transmission Treatments

Engine Treatment (LB-ET-1001A)

BLI's Liquid Boron Engine Treatment provides long life friction and wear reduction in internal combustion engines. Simply add to engine oil at next oil change, Liquid Boron Engine Treatment goes to work lubricating and protecting vital engine components.

Benefits

Detail Description

BLI’s Liquid Boron Engine Treatment is formulated to be added to any engine oil in any two-cycle or four-cycle internal combustion engine. The unique formulation introduces Liquid Boron into the engine creating a chemical reaction bonding process between the internal metal components and BLI’s Liquid Boron. Having an extremely strong affinity to metals, Liquid Boron, displaces sludge and varnish as it seeks to bond with the metals. This produces a boric-oxide boundary surface very close to diamond hardness with superior friction reducing lubrication, decreasing wear and warding off future sludge buildup.

Liquid Boron Engine Pre-Treatment prepares the internal metal surfaces by cleaning and removing contamination, allowing the Liquid Boron bonding process of Liquid Boron Engine Treatment to quickly establish the bonded surface and begin reducing friction. Because of the boric-oxide surface bonding, sludge, gums and varnish, and other deposits can no longer attach to these surfaces. A clean engine is more efficient than a dirty engine and Liquid Boron Engine Treatment helps to sustain that cleanliness by not allowing the aforementioned contamination to adhere to the metals internally. This promotes longer engine life and extended engine oil life since the engine oil additive chemistry does not have to work as hard.

For more information view PDS. Contact us directly for MSDS.

Applications

For all gasoline and diesel four cycle engines including:

Commercial - Class 7 & 8 Tractors, Class 5 & 6 Box Trucks, Refrigeration (Reefers), Delivery Trucks/Vans

Government - Law Enforcement Fleets, Fire Protection, LNG Fleets, Utility Fleets, Generators

Industrial - Generators, Fork Trucks, Loaders

Construction - Dump Trucks, Straight Trucks, Excavators/Loaders, Bulldozers, Generators, Medium Duty Trucks, Pickup Trucks

Drilling/Fracking - Generators, Class 7 & 8 Tractors

Agriculture - Farm Tractors, Combines, Medium Duty Trucks

Marine - Tugs, Charters, Yachts, Sport Fishing, Houseboats, Pontoon Boats, Bass Boats

Personal - Automobiles, Light Duty Trucks, SUVs, Motorhomes/RVs, Boats, ATV/Motorcycles,

Engine Pre-Treatment (LB-EPT-1002A)

BLI's Liquid Boron Engine Pre-Treatment is a specially formulated base oil designed to clean away sludge and other contaminants preparing engine component surfaces for BLI's Liquid Boron Engine Treatment.

Benefits

Detail Description

BLI’s Liquid Boron Engine Pre-Treatment is a combination of base oils designed to be used in any engine oil for the purpose of preparing internal surfaces for the patent pending bonding process of BLI’s Liquid Boron Engine Treatment. This important first step is recommended to be performed during a scheduled oil change.

Normal operating conditions of internal combustion engines generate contaminants - sludge, varnish, corrosive acids, carbon residue, ash deposits and wear metals. These contaminants deteriorate the engine oil and can contribute to premature component failures. Liquid Boron Engine Pre-Treatment removes these contaminants from internal component surfaces by dissolving and cleaning the contaminants from the surfaces. This pre-treatment prepares the internal metal surfaces for the unique bonding of Liquid Boron Engine Treatment, ensuring a fast and effective bond.

For more information view PDS. Contact us directly for MSDS.

Applications

Liquid Boron Engine Pre-Treatment can be used with any type and grade of engine oil. The most cost effective method for applying this product is to perform a pre-treatment at a regularly scheduled oil change.

Effective in all types of internal combustion engines both gasoline and diesel.

Gearbox & Differential Treatment (LB-GEAR-1003A)

BLI's Liquid Boron Gearbox & Differential Treatment treats the metal components in gearboxes and differentials providing long lasting friction and wear reduction. Simply add to the gear oil and Liquid Boron begins providing superior wear protection.

Benefits

Detail Description

BLI’s Liquid Boron Gearbox & Differential Treatment reduces friction by cleaning and then lubricating and protecting gears and bearings with a diamond hard boric-oxide bonded surface. BLI’s Liquid Boron Gearbox & Differential Treatment is formulated to be added to any gear oil in any gearbox, differential or manual transmission. It is not intended for use in automatic transmissions. The unique formulation introduces BLI’s Liquid Boron into the gearbox and differential creating a chemical reaction bonding process between the internal metal components and the Liquid Boron. Having an extremely strong affinity to metals, Liquid Boron, displaces sludge and varnish as it seeks to bond with the metals. This produces a boric-oxide boundary surface very close to diamond hardness with superior friction reducing lubrication, decreasing wear and warding off future sludge buildup.

Liquid Boron Gearbox & Differential Treatment works to quickly establish the bonded surface and begin reducing friction. Because of the boric-oxide surface bonding, sludge, gums and varnish, and other deposits can no longer attach to these surfaces. Reduced friction, running a cleaner gearbox allows for better heat transfer and reduced temperatures. Clean gears and bearings are more efficient than dirty components and Liquid Boron Gearbox & Differential Treatment helps to sustain that cleanliness by not allowing the aforementioned contamination to adhere to the metals internally. This promotes longer gear and bearing life and extended gear oil life since the gear oil additive chemistry does not have to work as hard.

For more information view PDS. Contact us directly for MSDS.

Applications

Compatible with all mineral, semi-synthetic or synthetic gear oils. Unlike normal additive chemistry in gear lubricants BLI's Liquid Boron Gearbox & Differential Treatment is a metal treatment and is stronger and much more stable under normal wear, loads and shock loads.

Add to existing gearbox, differential, manual transmissions, or trailer hub lubricants at a mix rate of 20:1.

2-Cycle Engine Treatment (LB-2CY-1004A)

BLI's Liquid Boron 2-Cycle Engine Treatment improves engine efficiency by cleaning and lubricating two cycle system components. Liquid Boron chemistry persists in the fuel system providing long lasting friction and wear reduction. Simply add to fuel at next fill up, Liquid Boron 2-Cycle Engine Treatment goes to work lubricating and protecting vital engine components.

Benefits

Detail Description

Liquid Boron 2-Cycle Engine Treatment is a uniquely formulated treatment for all 2-cycle gasoline engine applications. Liquid Boron 2-Cycle Engine Treatment produces an exclusive boric oxide bonded surface on all metal components. This unique chemistry has a strong affinity for metals reacting through varnish and gums and dissolving carbon residues normally found in 2-cycle engines. Liquid Boron 2-Cycle Engine Treatment chemistry improves lubrication protection and provides a consistent clean burn allowing the engine to run more efficiently.

For more information view PDS. Contact us directly for MSDS.

Applications

Liquid Boron 2-Cycle Engine Treatment will blend with any 2-cycle gasoline / oil mix. Introduce product to fuel at 500:1 mix ratio.

Bass boats, flats boats and other marine watercraft, lawn care equipment, motorcycles, mopeds, snowmobiles and any 2-cycle engine application.

BLI's Liquid Boron fuel treatments provide significant benefits in diesel, gasoline and ethanol-gasoline fuel blends. The Liquid Boron chemistry provides superior lubrication and wear protection to the fuel system components improving performance and maintaining a clean fuel system. BLI's Liquid Boron chemistry persists in the fuel system providing long lasting friction and wear reduction.

In both diesel and ethanol fuel blends, Liquid Boron fuel treatments address water and ethanol solvency issues that are prevalent in all of today's fuel blends. Improving combustion efficiency and protecting fuel system components.

Fuel System Treatments

Diesel Fuel Treatment (LB-ET-1001A)

BLI's Liquid Boron Diesel Fuel Treatment improves engine efficiency by cleaning and lubricating diesel fuel system components and providing a diamond hard protective boundary surface on all fuel system components. Simply add to fuel at next fill up, Liquid Boron Diesel Fuel Treatment goes to work lubricating and protecting vital engine components.

Benefits

Detail Description

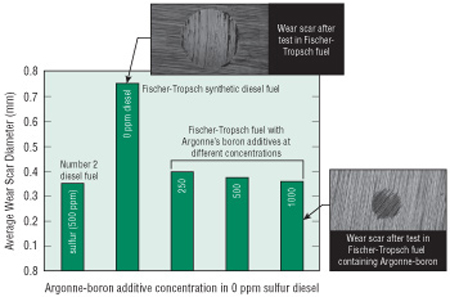

Fuel lubricity performance wear scar testing from Argonne National Laboratory. Boron additive provides improved protection.

BLI’s Liquid Boron Diesel Fuel Treatment is a formulated fuel system treatment compatible with all types of diesel fuels, including ultra-low sulfur (ULSD), bio-diesel and ethanol-diesel fuel blends. Liquid Boron Diesel Fuel Treatment is simply poured into the fuel where the product blends, cleaning components throughout the fuel and combustion system allowing Liquid Boron to bond with the metal components creating the diamond hard boric-oxide lubricating and protective surface.

The treatment cleans and will reduce or eliminate gums and varnish buildup, which in turn cause carbon residue buildup. Preventing these contaminants from buildup in fuel and combustion components will result in improved combustion efficiency and better performance.

For more information view PDS. Contact us directly for MSDS.

Applications

For all diesel engines including:

Commercial - Class 7 & 8 Tractors, Class 5 & 6 Box Trucks, Refrigeration (Reefers), Delivery Trucks/Vans

Government - Fire Protection, Utility Fleets, Generators

Industrial - Generators, Fork Trucks, Loaders

Construction - Dump Trucks, Straight Trucks, Excavators/Loaders, Bulldozers, Generators, Medium Duty Trucks

Drilling/Fracking - Generators, Class 7 & 8 Tractors

Agriculture - Farm Tractors, Combines, Medium Duty Trucks

Marine - Tugs, Charters, Yachts, Sport Fishing

Personal - Automotive Diesels, SUVs, Motorhomes/RVs

Available in the USA for off-road (nonroad) use ONLY pending EPA approval for highway use. Off-road and marine use in the USA ONLY.

Gasoline & Ethanol Fuel Treatment (LB-EFT-1007A)

BLI's Liquid Boron Gasoline & Ethanol Fuel Treatment is a multi-functional fuel treatment that stabilizes gasoline fuel blends, lubricates and protects components from wear, rust and corrosion.

Benefits

Description

BLI’s Liquid Boron Gas & Ethanol Fuel Treatment for four stroke gasoline engines is a formulated fuel system treatment compatible with all grades of petrol/gasoline especially ethanol-gasoline fuel blends E10, E15, all the way up through E85. Liquid Boron Gas & Ethanol Fuel Treatment is simply poured into the fuel where it begins cleaning components throughout the fuel and combustion system and the unique Liquid Boron begins to bond with metal components creating a diamond hard protective surface. The unique Liquid Boron bonding cleans injector nozzles and works to keep the injectors clean maintaining optimal fuel spray patterns and optimal combustion efficiency.

Liquid Boron bonding protects moving components in the fuel system, developing less friction, protecting against wear and eliminating the buildup of gums, varnish and carbon residue without affecting fuel additives. This unique formulation will help keep fuel lines from gum and varnish buildup and will reduce fuel pump downtime simply by allowing the system to run cleaner and stay cleaner.

Liquid Boron stabilizes moisture in ethanol and gasoline blends allowing for complete and improved combustion eliminating rough starting and rough running. This treatment continues to control moisture providing long term fuel stabilization and prevents algae growth.

For more information view PDS. Contact us directly for MSDS.

Applications

Liquid Boron Gas & Ethanol Fuel Treatment is recommended for four-stroke petrol/gasoline engines. Compatible with all grades of modern petrol/gasoline fuel blends including ethanol fuel blends E10 through E85.

Automobiles, Class 1—3 Light Duty trucks, motorcycles and all types of gasoline fueled boats and marine craft.

Available in the USA for off-road (nonroad) use ONLY pending EPA approval for highway use. Off-road and marine use in the USA ONLY.

2-Cycle Engine Treatment (LB-2CY-1006A)

BLI's Liquid Boron 2-Cycle Engine Treatment improves engine efficiency by cleaning and lubricating two cycle system components. Simply add to fuel at next fill up, Liquid Boron 2-Cycle Engine Treatment goes to work lubricating and protecting vital engine components.

Benefits

Detail Description

Liquid Boron 2-Cycle Engine Treatment is a uniquely formulated treatment for nearly all 2-cycle gasoline engine applications. Liquid Boron 2-Cycle Engine Treatment produces an exclusive boric oxide bonded surface on all metal components. This unique chemistry has a strong affinity for metals reacting through varnish and gums and dissolving carbon residues normally found in 2-cycle engines. Liquid Boron 2-Cycle Engine Treatment chemistry improves lubrication protection and provides a consistent clean burn allowing the engine to run more efficiently.

For more information view PDS. Contact us directly for MSDS.

Applications

Liquid Boron 2-Cycle Engine Treatment with blend with any 2-cycle gasoline / oil mix. Introduce product to fuel at 500:1 mix ratio.

Bass boats, flats boats and other marine watercraft, lawn care equipment, motorcycles, mopeds, snowmobiles and any 2-cycle engine application.

BLI's Liquid Boron industrial lubricants and treatments bring it! "It" is diamond hard wear protection and superior friction reduction. These characteristics of the Liquid Boron family of products are even more impressive in the everyday harsh environment of high temperature oven chains, extreme duty gearboxes and critical application grease protection.

Industrial Lubricants and Treatments

Liquid Boron Gear Lubricant, ISO Grade: 220 & 320 (LB-IND-2002)

Liquid Boron Gear Lubricant is a specially formulated gear lubricant for tough industrial applications available in ISO Grade 220 and 320.

Benefits

Detailed Description

Liquid Boron Gear Lubricant is specially formulated to reduce internal friction through a patented lubrication additive. This unique formulation forms a multi-layered platelet film on metal surfaces which has very low sliding friction between layers. Even though the individual layers slide easily over each other, any given layer has a hardness approaching that of diamond hardness. This combination of strong individual layers with low internal friction gives a number of special benefits, such as excellent anti-wear and micropitting protection combined with energy efficiency. Unlike other low-friction technologies which rely on solid nanoparticles dispersed in oil the Liquid Boron additive is completely soluble in the lubricant.

The unique Liquid Boron additive works to quickly establish the bonded surface and begin reducing friction. The surface film inhibits sludge, gum, and varnish formation. Reduced friction, coupled with a cleaner gearbox, allows for better heat transfer and reduced operating temperature. The Liquid Boron Gear Lubricant promotes longer gear and bearing life, as well as extended lubricant life.

For more information view PDS. Contact us directly for MSDS.

Applications

Liquid Boron Gear Lubricant is recommended for all stationary, enclosed industrial gearboxes especially those requiring a lubricant meeting the specifications:

AGMA 9005-F AS

AIST (US Steel) 224

HT Oven Lubricant (LB-IND-2001)

High Temperature (HT) Oven Lubricant is a breakthrough chain lubricant providing superior wear protection at temperatures up to 2,000 F.

Benefits

Detailed Description

BLI's Liquid Boron HT Oven Lubricant is specially formulated to provide chain lubrication protection at extremely high termperatures up to 2,000 F. This unique formulation is ashless and does not leave residue on the chain components. Liquid Boron HT Oven Lubricant will not build varnish and carbon residue commonly found on many chain applications.

BLI's Liquid Boron HT Oven Lubricant is formulated with the unique patents pending Liquid Boron chemistry. Liquid Boron HT Oven Lubricant provides a high natural detergency action which cleans residue from components allowing the Liquid Boron chemistry to bond and penetrate the lubrication points providing extreme wear protection for sprockets, chain rollers, bushings, pins and rails. Exceptional wear protection on chains extends the life of sprockets and provides for a much longer chain life in turn reducing oven downtime.

For more information view PDS. Contact us directly for MSDS.

Applications

Apply with an automated spray system. HT Oven Lubricant works in water and salt spray environments.

Foundry - Annealing Ovens, Kilns

Food Processing - Ovens, Bakeries

Gearbox & Differential Treatment (LB-GEAR-1003A)

BLI's Liquid Boron Gearbox & Differential Treatment treats the metal components in gearboxes and differentials providing long lasting friction and wear reduction. Simply add to the gear oil and Liquid Boron begins providing superior wear protection.

Benefits

Detail Description

BLI’s Liquid Boron Gearbox & Differential Treatment reduces friction by cleaning and then lubricating and protecting gears and bearings with a diamond hard boric-oxide bonded surface. BLI’s Liquid Boron Gearbox & Differential Treatment is formulated to be added to any gear oil in any gearbox, differential or manual transmission. It is not intended for use in automatic transmissions. The unique formulation introduces BLI’s Liquid Boron into the gearbox or differential creating a chemical reaction bonding process between the internal metal components and the Liquid Boron. Having an extremely strong affinity to metals, Liquid Boron, displaces sludge and varnish as it seeks to bond with the metals. This produces a boric-oxide boundary surface very close to diamond hardness with superior friction reducing lubrication, decreasing wear and warding off future sludge buildup.

Liquid Boron Gearbox & Differential Treatment works to quickly establish the bonded surface and begin reducing friction. Because of the boric-oxide surface bonding, sludge, gums and varnish, and other deposits can no longer attach to these surfaces. Reduced friction, running a cleaner gearbox allows for better heat transfer and reduced temperatures. Clean gears and bearings are more efficient than dirty components and Liquid Boron Gearbox & Differential Treatment helps to sustain that cleanliness by not allowing the aforementioned contamination to adhere to the metals internally. This promotes longer gear and bearing life and extended gear oil life since the gear oil additive chemistry does not have to work as hard.

For more information view PDS. Contact us directly for MSDS.

Applications

Compatible with all mineral, semi-synthetic or synthetic gear oils. Unlike normal additive chemistry in gear lubricants BLI's Liquid Boron Gearbox & Differential Treatment is a metal treatment and is stronger and much more stable under normal wear, loads and shock loads.

Works great in single or multi-reduction gearboxes and speed reducers - bevel gears, helical gears, spur gears, planetary gears and worm gears. Will not harm yellow metals such as worm gears. Also works well in gearmotor applications.

If application includes clutches or internal breaking requiring friction do NOT use this product.

Add to existing gearbox, differential, manual transmissions, or trailer hub lubricants at a mix rate of 20:1.